HEAVYTORQUE VISITS CHESHIRE-BASED CRANAGE HEAVY HAULAGE TO FIND OUT HOW THIS NATION-WIDE OPERATION GREW FROM ITS HUMBLE FOUNDATIONS

Presenting a positive image is an important factor in any industry, more than ever, a customer’s first impression of a company is heavily influenced by initial contact, which in specialist transport is very often the physical appearance of the equipment it owns and the staff it employs. Gareth Edwards, the youthful boss of Cranage Heavy Haulage is a firm believer in this theory and the company takes great pride in the vehicles and trailers it operates and feels that this has helped the company win new business over the past decade or so.

This modern approach to business works in conjunction with the family’s long involvement in transport. His father Gary drove for other companies for a number of years before starting out as an owner driver. Time spent moving caravans and plant, with vehicles like a humble Ford D series, eventually made way for better equipment as things progressed. Gary still prefers the hands-on approach in the modern business and is much happier behind the wheel of an 80-tonne Scania R730 6×4, with a trusty Nokia mobile phone, rather than grappling with modern technology back at base. Sounds eminently sensible to us!

WITH INCREASING VOLUMES OF TRAFFIC AND THE RELATIVE LACK OF AWARENESS SHOWN BY SOME MOTORISTS THERE WAS AN URGENT NEED FOR BETTER TRAINED STAFF TO UNDERTAKE THE VITALLY IMPORTANT ROLE OF ESCORTING ABNORMAL LOADS. HEAVYTORQUE EXPLAINS THE BACKGROUND TO THE NEW CITY & GUILDS QUALIFICATIONS.

The Abnormal Load Escort Certificates of Competence, which were launched by the Heavy Transport Association (HTA) in early 2017, are the result of a long and exhaustive process between the HTA, various regulatory bodies, industry representatives and the City and Guilds organisation. These much-needed qualifications bring a framework of effective training and two distinct qualifications to the business of providing safe and effective escorting of large abnormal loads on British roads. Previously there was no formal training available for this function and the industry was forced to start providing private escorts in 2004, when police forces began to withdraw from routinely escorting abnormal loads. A code of practice for private escorts was drawn up by the Highways Agency later that year, but many operators had already made their own ad-hoc arrangements, which differed considerably in terms of effectiveness.

Issue Fourteen: with 172 pages of first-class journalism and photography, what more can you wish for? HeavyTorque, Britain’s best loved specialist transport title! Click the appropriate link below to purchase your annual subscription, or individual copy.

WEST SUSSEX-BASED SOUTHERN RECOVERY SERVICE HAS A FAYMONVILLE MULTIMAX PA-X STEP-FRAME, ALMOST CERTAINLY THE HIGHEST SPECIFICATION RECOVERY TRAILER CURRENTLY IN THE UK. HEAVYTORQUE MEETS DIRECTOR PAUL ATTWATER TO FIND OUT HOW IT FITS INTO THE COMPANY’S DIVERSE OPERATION.

Heavy vehicle recovery has become a very sophisticated business in recent years. Vehicles are bigger, heavier and often more fragile and difficult to lift and tow when broken down. Heavy traffic volumes on motorways and other major routes mean that if a heavy vehicle goes out of control it often causes a lot of damage, involves other vehicles and quite often ends up quite a long way off the carriageway. These and many other factors mean that specialist recovery companies have had to invest in specialist equipment to lift and pull vehicles upright and get them back onto hard standing.

Another vital factor is safety when working at the roadside. Motorway hard shoulders and roadside verges are dangerous places. Many drivers seem to be oblivious to their surroundings. Warning beacons, road cones, closed lanes, even police and traffic officers’ marked vehicles fail to get the attention of some clowns.

TREVOR JEPSON HEADS UP CITY LIFTING, ONE OF THE BIGGEST SPECIALIST LIFTING COMPANIES IN THE SOUTH EAST, AND AFTER NEARLY 40 YEARS IN THE BUSINESS, HE’S CERTAINLY BEEN THERE, DONE IT, AND GOT THE T-SHIRT. HEAVYTORQUEWENT TO MEET HIM, TO FIND OUT HOW IT’S DONE.

If you think the heavy haulage business is riddled with regulation and red tape, try talking to a heavy lifting expert. “I am basically an enthusiast in this specialised sector, you have to be to keep up with the Byzantine rules and regulation. We do sometimes feel as if we are an inconvenient truth,” says Jepson. The clue to the company’s orbit is in the name. The majority of its work is inside the M25, with much of it involving highly specialised lifts in the city of London.

Jepson started his working life as a toolmaker in Leyton High Road, but he, against his wise mother’s advice, decided that he would be better off at 19 joining his father’s crane hire business. His father got into crane hire by accident as three cranes were salvaged from the receivership of his sizable construction business which operated from premises in Bow.

Issue Fourteen: with 172 pages of first-class journalism and photography, what more can you wish for? HeavyTorque, Britain’s best loved specialist transport title! Click the appropriate link below to purchase your annual subscription, or individual copy.

WITH A HERITAGE IN AGRICULTURAL CONTRACTING AND HAULING ANIMAL FEED CORNERS TRANSPORT IS A THIRD-GENERATION OPERATOR THAT HAS EVOLVED AND FLOURISHED WITH CRANE-MOUNTED VEHICLES SPECIALISING IN STGO CAT 2 HEAVY-HAULAGE AND FORKLIFT TRANSPORT. AS HEAVYTORQUE DISCOVERS, IT’S A COMPANY LOOKING TO EXPAND EVEN FURTHER.

Chronicling any transport company is difficult because the markets in which they operate continually change, either for the better or worse. However, there’s an enduring theme when it comes to Corner’s Transport that helps makes sense of history and where it is today, and that is diversification.

Officially, according to Companies House, Corner’s Transport was incorporated in January 2013 and is the culmination of two previous transport businesses; TF Corner and SC Transport. Combined these haulage companies stretch back 75 years and all three have run out of Arlaw Banks, Winston, on the A67 between Barnard Castle and Darlington, Co Durham.

TF Corner was started by Thomas Corner in 1953 as an agricultural contractor. He ran an ex-army wagon hauling cattle.

IN THE SECOND OF OUR CONVERSATIONS WITH A CHASSIS MANUFACTURER’S HEAVY-HAULAGE SPECIALIST HEAVYTORQUE TALKS TO VOLVO’S DUNCAN SEAMAN AND HEARS WHY IT’S IMPORTANT TO THINK BACK-TO-FRONT WHEN SPECCING AN STGO TRACTOR.

We all like a take-away. Duncan Seaman, heavy haulage product specialist at Volvo Trucks UK & Ireland gets his from truck operators. “Every day’s a school day for me. I learn a lot from the customers, because they know more than I do.” Not that Seaman is a slouch when it comes to broad engineering experience.

As a young British Rail Engineering apprentice at Crewe in the late ‘70s he spent time refurbishing 2,750hp Brush Sulzer Class 47 diesel locos. And while studying for his HND in Mechanical Engineering, he destruction-tested electrical switch gear for nuclear power plants while on industrial placement with GEC. “We were making sure that in all scenarios you could bring the reactor under control” he says reassuringly.

Issue Fourteen: with 172 pages of first-class journalism and photography, what more can you wish for? HeavyTorque, Britain’s best loved specialist transport title! Click the appropriate link below to purchase your annual subscription, or individual copy.

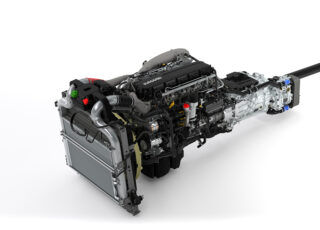

WITH THE MAJOR TRUCK MANUFACTURERS ALL HAVING FINALISED THEIR ENGINE LINE-UPS FOR EURO VI ON-BOARD DIAGNOSTIC (OBD)-C, NOW IS THE TIME TO REVIEW THE DRIVELINES ON OFFER FOR GROSS WEIGHTS OF OVER 44 TONNES. HEAVYTORQUE REPORTS.

Truck manufacturers utilising increased low-end torque to maintain road speed while reducing fuel consumption is a trend which has accelerated with the introduction of the latest Euro VI OBD-C emissions requirements. Engines themselves have reached standards of environmental cleanliness thought unattainable by diesel just a few years ago; and independent tests reveal that in terms of pollutants produced per mile travelled, today’s heavy-duty diesel engines are actually cleaner than many of their light-duty counterparts. These very welcome improvements do mean, however, that careful attention must be paid to the specification of dual-purpose and dedicated heavy-haulage tractors.

As one industry insider put it to us: “If you are replacing a truck that is five years old, then there is no such thing as a like-for-like replacement. Probably the only part that won’t be new is the cab: everything else from engine to drive-axle will have been substantively changed.”

Issue Fourteen: with 172 pages of first-class journalism and photography, what more can you wish for? HeavyTorque, Britain’s best loved specialist transport title! Click the appropriate link below to purchase your annual subscription, or individual copy.