STARTING OUT IN 1976 WITH A SINGLE FORD “D” SERIES TRUCK, CHRIS BENNETT HEAVY HAULAGE, BASED IN BREDBURY, GREATER MANCHESTER, HAS GROWN TO BECOME A LEADING OPERATOR OF HEAVY FREIGHT AND GENERAL HAULAGE. HEAVYTORQUE MEETS THE FAMILY.

Building and sustaining a heavy haulage operation for over four decades is a considerable achievement, especially with the dramatic changes that the UK’s industrial base has undergone in this period. Back in the 70’s many of our northern towns had scores of heavy engineering and metal fabrication companies on almost every corner, this created strong demand for specialist hauliers to transport their products to construction sites, large industrial plants and the docks for export. Most operators were able to work within their own area for most of the time, even loads that took them to other parts of the country were invariably on behalf of local customers.

While we still have a considerable amount of heavy industry, much of it is now widely spread around the country. The heavy haulier has to be prepared to travel far and wide if that is what the customer demands. In addition, they have to offer a wide range of services in order to meet the needs of clients.

WITH OVER 100 YEARS’ EXPERIENCE IN THE MOVING AND INSTALLATION OF COMPLEX MACHINERY, BATLEY-BASED J EXLEY CONTINUALLY INNOVATES FOR INDUSTRY. HEAVYTORQUE VISITS AN ESTABLISHED OPERATION THAT IS MOVING AHEAD OF THE TIMES.

100 years ago Batley, a small town to the south of Leeds in West Yorkshire, was a very different place. Textiles were the thing, and numerous small businesses sprung up alongside the thriving mills to provide the industry with all the peripheral services it needed. “There were 40 mills just between Birstall and Dewsbury,” says Greg Exley, managing director of J Exley speaking in his office halfway down the Bradford Road. Exley’s great grandfather started the business over 100 years ago and the family has been both living and working in this yard since the 1930s. Greg Exley is the fourth generation to have the reins of the family business – a very different company to the one Joah Exley first built.

“They started off doing something with steam piping,” Exley tells us. “Then they were making leather belts, because obviously everything was line-shaft driven.” This in turn led to work reconditioning textile machines meaning they needed to be removed and transported, the bit the company specialises in today.

Issue Seventeen: with 156 pages of first-class journalism and photography, what more can you wish for? HeavyTorque, Britain’s best loved specialist transport title! Click the appropriate link below to purchase your annual subscription, or individual copy.

AFTER NEARLY TWO YEARS, THE NEW SCANIA TRUCK RANGE IS NOW COMPLETE WITH THE HEAVY HAULAGE TRACTORS BEING THE LAST OF THE SERIES TO BE LAUNCHED. HEAVYTORQUE VISITS GLOUCESTERSHIRE-BASED D C MERRETT AND CO WHICH RUNS THE FIRST NEW GENERATION S730 8X4 TRACTOR UNIT TO ENTER SERVICE IN THE UK.

The introduction of a completely new model range is a vitally important step for any truck manufacturer – the research, planning design and development process is invariably a lengthy, complex operation. This is then followed by the launch in various markets, involving regional dealer staff, the press, customers and other potential users. In addition, the production process has to be devised implemented and streamlined to hopefully meet predicted demand. Meanwhile supply chains with component suppliers have to be established and perfected, otherwise the vehicle production line will not function efficiently.

Other less visible preparations have to be made, including sales and aftermarket staff training, parts supply, bodybuilder and other associated supplier documentation and accreditation. Even the most basic of publications such as vehicle driver’s handbooks have to be written, checked and available on time.

PHIL ROOTHAM, SCANIA’S PRE-SALES TECHNICAL MANAGER, EXPLAINS TO HEAVYTORQUE HOW THE SWEDISH MANUFACTURER RATES ITS HEAVY HAULAGE CHASSIS ON THEIR DESIGN CAPABILITIES, NOT JUST STGO ‘BREAK-POINTS’.

When we ask Phil Rootham how he got started in the business he tells us: “I think it might be a little bit of a stereotype.” We obviously look blank before he explains “…a stereotype of all your other interviews!” Ahh…now we get it. Having read the comments of previous manufacturer interviewees in HeavyTorque, Rootham says he shares a similar ‘early indoctrination’ into the industry with them. “I had two uncles, one drove trucks, the other was a mechanic. The one who was the mechanic maintained lots of other independent hauliers’ vehicles and his business slowly turned into a workshop. I started working for him on Saturday mornings at the age of 12 oiling padlocks and fetching bacon sandwiches.” But what was the attraction of trucks at that tender age? Rootham reckons: “I had an interest in vehicles, and how things worked. For me it was always about how everything came together at a single point.”

So when the 16-year-old Rootham was offered an apprenticeship at his Uncle’s garage it seemed a natural path to follow. “It became an opportunity to follow that process” he says with a smile.

Issue Seventeen: with 156 pages of first-class journalism and photography, what more can you wish for? HeavyTorque, Britain’s best loved specialist transport title! Click the appropriate link below to purchase your annual subscription, or individual copy.

MCFADYENS TRANSPORT, WHICH OFFERS A WIDE RANGE OF SERVICES FOR THE WIND ENERGY SECTOR AND BEYOND, HAS RENOVATED A SCANIA LONGLINE TRACTOR UNIT AS ITS FLAGSHIP AND HISTORY ARTWORK GALLERY. HEAVYTORQUE RE-VISITS THE CAMPBELTOWN-BASED COMPANY TO FIND OUT HOW FAR IT HAS PROGRESSED, PARTICULARLY IN RECENT YEARS.

It’s very important for all long-established companies to acknowledge the history and development of the enterprise – this brings a sense of direction and achievement to any organisation. This is particularly relevant with family concerns, where different generations have striven to build the business, often taking the operation in new directions, making their own mark upon both the company and family history.

If a company has a keen sense of its development through the generations, there are numerous ways to celebrate this and one of the most obvious ways for a transport company to display its history is by having a special vehicle, a company flagship that really stands out and tells the story behind the business.

IN NOVEMBER HEAVYTORQUE ATTENDED AN EVENT HELD BY SARENS TO CELEBRATE THE INTRODUCTION OF THE LARGEST CRANE IN ITS FLEET. ITS INITIAL TASK WILL BE THE CONSTRUCTION OF HINKLEY POINT NUCLEAR POWER STATION.

The giant SGC-250, was launched at an event in the port of Ghent, Belgium. The machine is currently regarded as the largest crane in the World in both size and capacity. Chief executive officer Wim Sarens, and director of technical solutions, projects, and engineering, Carl Sarens, presented the crane from a commercial and technical standpoint to the audience.

The SGC-250 is the first of the third-generation of ring-based cranes at Sarens. It has a maximum load moment of 250,000tonnes/m which allows the lifting of an astonishing 5,000 tonnes. Even at a large radius of 100m, the crane is still capable of lifting 2,000 tonnes and, even when doing so, the ground pressure remains below 25tonnes/m². This is achieved through the high number of wheel bogies on the double ring beams and the spreader mats that the machine features.

Issue Seventeen: with 156 pages of first-class journalism and photography, what more can you wish for? HeavyTorque, Britain’s best loved specialist transport title! Click the appropriate link below to purchase your annual subscription, or individual copy.

AVONMOUTH-BASED KINGS HEAVY HAULAGE IS A SUBSTANTIAL FAMILY-OWNED CONCERN THAT HAS MAINTAINED A STRONG PRESENCE IN SPECIALIST TRANSPORT, PARTICULARLY IN THE WEST COUNTRY, SINCE 1969. HEAVYTORQUE CHARTS ITS HISTORY.

There are certain long-established heavy transport companies that are invariably associated with the part of the country in which they are based, they are the backbone of the industry, have dealt with the peaks and troughs of business over the decades and continue to thrive in the modern world. Kings Heavy Haulage is a perfect example of this effect.

Kings’ red and white fleet of trucks, predominately Volvo since the 70’s, continues to be a regular sight throughout the UK and Europe. The company was featured on prime-time TV, giving the general public an insight into specialist road transport. The business has endured economic downturns and faced various challenges, but is thriving with big plans for the future, not least celebrating its 50th anniversary in 2019.

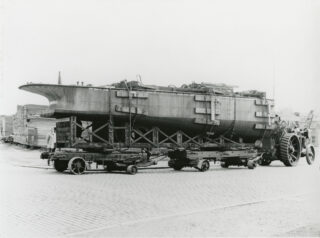

BUILT IN 1894, THE EXPERIMENTAL STEAM LAUNCH TURBINIA, IS AN INTEGRAL PART OF MARITIME HISTORY AND WAS ONCE THE FASTEST SHIP IN THE WORLD. HOWEVER, ON THREE OCCASIONS IT’S BEEN MOVED AT A SNAIL’S PACE BY ROAD, AS HEAVYTORQUE REPORTS.

As a publicity stunt, it was audacious, but brilliant. In 1897, Tyneside engineer Charles Parsons wanted to show off his steam turbine-powered vessel, Turbinia. Where better than the Navy Review as part of the celebrations of Queen Victoria’s Diamond Jubilee at Spithead? But he hadn’t been invited! So Turbinia gate-crashed the party, steaming in and out of the Navy’s ponderous warships at unprecedented speeds of 35 knots, and easily escaping from the Navy picket boats that were sent out to apprehend it.

But the Navy had seen enough, and soon ordered new warships powered by Parsons’ innovative engines, including the revolutionary HMS Dreadnought. Operators of merchant vessels were similarly impressed. Thomas Ismay, president of the White Star Line, was invited on board Turbinia, and Cunard’s RMS Mauretania, at the time the world’s largest ship, was launched on Tyneside in 1906. Parsons’ turbines allowed it to claim the Blue Riband for the fastest crossing of the Atlantic Ocean, a record she held for twenty years.

Issue Seventeen: with 156 pages of first-class journalism and photography, what more can you wish for? HeavyTorque, Britain’s best loved specialist transport title! Click the appropriate link below to purchase your annual subscription, or individual copy.