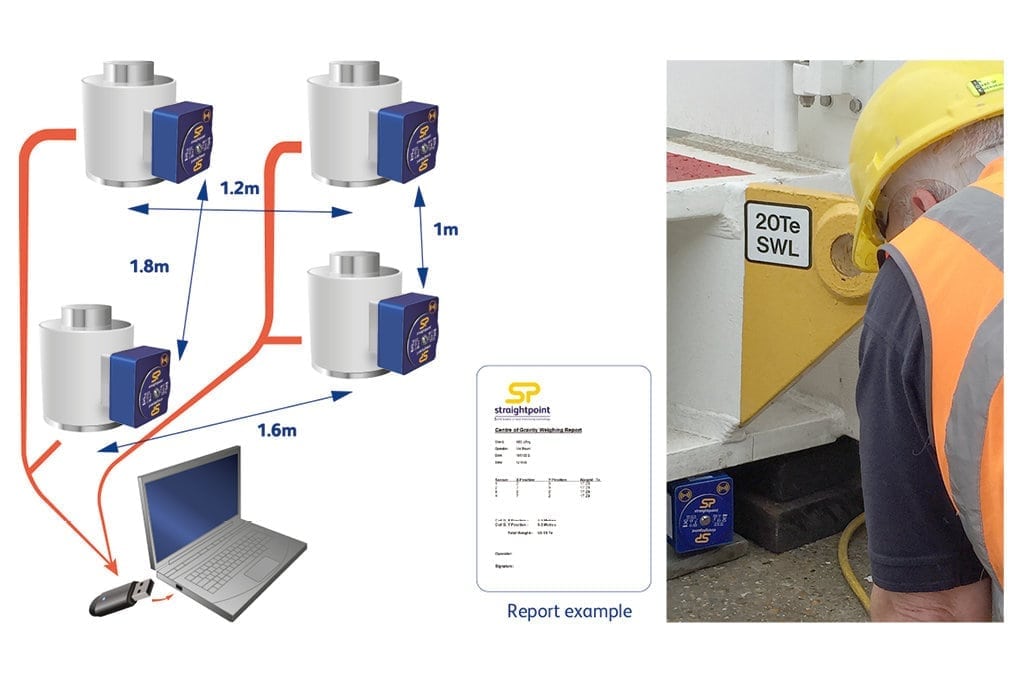

Four wireless compression load cells with centre of gravity software were used to weigh two subsea fabricated platforms at Pentalver’s shipping facility at Southampton Docks, UK recently.

Straightpoint supplied the 50t WNI50TC load cells to Rapid Response Solutions, which was tasked with weighing the remotely operated underwater vehicle (ROV) launching platform for Metcalfe Farms Heavy Haulage. There was a discrepancy on weight between the shipping company and the manufacturer and an accurate weight was required from a third party.

Stuart Trinder, the business development associate for projects at Rapid Response, explained that a container handler was used to lift the platforms, which measured 6m long by 2.5m wide and eventually weighed in at just over 36t apiece.

He said: “Once the ROV launching platform was safely lifted, we placed wooden blocks under the unit and lowered it. We then used hydraulic jacks to lift the platform enough to place the wireless compression load cells into position and lowered the platform.”

The centre of gravity software was loaded onto a laptop, allowing Trinder and the lift team to receive real time data wirelessly from the units and send a PDF containing the data instantly to the client. Rapid Response is a regular user of Straightpoint equipment, but has more commonly used its calibration services.

Trinder said: “Over the last year we have seen an increase in the need for load monitoring equipment, which is a trend set to continue as our client base in the marine sector grows. Both myself and Jon Blampied, our lift supervisor, were greatly impressed with the wireless technology and the real time reporting facility. The ease of use was also very impressive, given this was the first time we have used the wireless load cells with centre of gravity software.”

Trinder anticipates that the success of the Metcalfe Farms Heavy Haulage job will contribute to ongoing demand for load monitoring. He said: “The centre of gravity and wireless compression cells allow us to offer an extra service to clients. The accuracy and reliability of the equipment, coupled with the ease of use and portability, was key to the successful outcome of the platform weighing project and will no doubt lead to future opportunities.”

“The distribution partnership we now have with world renowned load monitoring heavyweight Straightpoint will allow both businesses to benefit. We are looking to work together on projects in the future and thus further enhance both our reputations within the industry,” Trinder concluded.

Straightpoint director David Ayling said: “Our wireless, out-of-the-box solution for weighing and centre of gravity calculation is proving more and more useful for forward-thinking companies like RSS, who are adding value to their services by embracing the technology we can offer them.”

For more details on Straightpoint’s Wireless Centre of Gravity System, please visit;

http://www.straightpoint.com/loadcell-software.html#wcogs